How Much Water Kitchens Waste When Thawing Food (With Real Numbers)

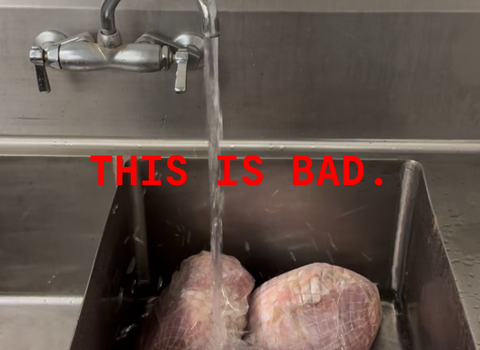

Thawing under a running faucet is still one of the most common practices in commercial kitchens, grocery stores, hotels, commissaries, and meat/seafood departments. Operators rely on it because it feels fast and familiar — but the amount of water wasted in the process is staggering.

This article breaks down how much water is actually used during faucet thawing, why the waste is far higher than most kitchens realize, and how modern technology reduces that waste by more than 98%.

1. The Real Flow Rate of Commercial Prep Sinks: 5–10 Gallons Per Minute

Residential faucets often run at 1.5–2.2 gallons per minute, but commercial prep sinks are dramatically different.

Most prep sinks in restaurant, grocery, or institutional kitchens run at:

5–10 gallons per minute (gpm)

This means even a short thawing session sends hundreds of gallons of potable water straight down the drain.

2. How Much Water Is Used During Typical Thawing Tasks?

Let’s break down common thawing scenarios.

Example: Thawing chicken, salmon, beef, or seafood under running water

Average thaw time: 20–60 minutes

Flow rate: 5–10 gpm

Water wasted per thaw:

-

20 minutes → 100–200 gallons

-

30 minutes → 150–300 gallons

-

45 minutes → 225–450 gallons

-

60 minutes → 300–600 gallons

These numbers are not theoretical — they reflect what kitchens actually experience.

For comparison resources, see:

👉 Why Running-Water Thawing Is Risky

👉 Cold Water vs Walk-In vs CNSRV

3. Large Proteins Are Even Worse

Turkey, pork shoulders, large briskets, and multi-pound vacuum-sealed proteins often require:

2–5 hours under running water

At 5–10 gpm, this results in:

-

2 hours → 600–1,200 gallons

-

3 hours → 900–1,800 gallons

-

4 hours → 1,200–2,400 gallons

-

5 hours → 1,500–3,000 gallons

This is why kitchens routinely waste thousands of gallons in a single shift without realizing it.

4. Annual Water Waste in a Typical Kitchen

If a kitchen thaws food under a faucet just twice per day:

-

300 gallons × 2 sessions = 600 gallons/day

-

That’s 18,000 gallons per month

-

And 216,000 gallons per year for one location

High-volume operations (hotels, grocers, commissaries) may exceed 1 million gallons of wasted water per year across repeated thaw cycles.

This aligns with the ICP study showing that a single kitchen can waste nearly a million gallons annually just on running-water thawing.

5. Why Faucet Thawing Wastes So Much Water

Most of the water never actually touches the product. Issues include:

-

Only a small portion of the food surface receives direct flow

-

Water runs continuously whether thawing is progressing efficiently or not

-

Warm pockets form around the product, slowing thawing and increasing water use

-

Operators often step away, allowing excessive run times

-

High flow rates multiply waste quickly

For the science behind immersion, see:

👉 Why Continuous Water Movement Matters in Food Thawing

6. How CNSRV Reduces Water Use by 98%

CNSRV eliminates running water entirely by using:

-

A closed-loop water environment

-

Full immersion of the product

-

Continuous circulation to prevent warm pockets

-

Regulated temperatures to keep thawing fast and safe

One fill of the unit (approximately 15 gallons) is reused throughout the cycle.

Water use per cycle with CNSRV:

≈ 15 gallons

vs.

300–600 gallons under a faucet

This is where the 98% water-savings figure comes from.

For more, see:

👉 CNSRV DC:02

7. The Cost of Wasted Water for Operators

Commercial water + sewer rates can reach:

-

$0.02–$0.04 per gallon in many cities

-

Hotels and large institutions often pay even more due to sewer surcharges

-

Hawaii and California can be significantly higher

At 200,000–1,000,000 gallons wasted per year, this translates to:

$4,000–$40,000 in annual water/sewer cost

for a single kitchen, depending on rates.

Multiply across multi-unit groups and the economics become enormous.

8. Bottom Line

Running-water thawing is one of the largest hidden sources of water waste in foodservice. With prep sinks flowing at 5–10 gallons per minute, even short thaw periods consume hundreds of gallons per session and hundreds of thousands per year.

CNSRV replaces this outdated practice with a controlled, efficient system that reduces water use by 98% while improving safety, speed, and consistency.