Is Your Kitchen Wasting Water? How Much — And What It’s Costing You

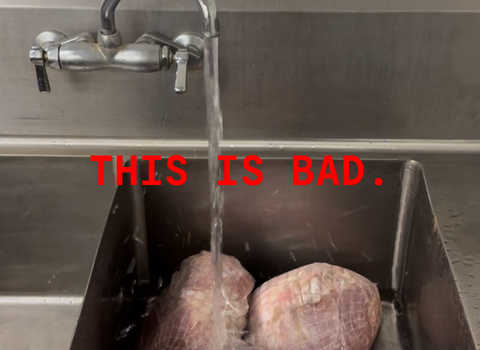

Commercial kitchens waste more water thawing food than almost any other back-of-house activity. The biggest culprit isn’t dishwashing, mop sinks, or ice machines.

It’s defrosting food under a running faucet — a method we break down in detail here:

Why Running-Water Thawing Is Risky

https://cnsrv.com/blogs/news/why-running-water-thawing-is-risky-the-hidden-safety-cost-and-compliance-problems

Across restaurants, hotels, grocery chains, and institutional kitchens, running water remains common simply because it’s familiar. But familiarity comes at a massive cost: water, money, labor, food quality, and safety.

Here’s how much this outdated method is really costing your operation.

How Much Water Does Running-Water Thawing Waste?

Most commercial prep sinks run between 5–10 gallons per minute.

Taking a conservative midpoint — 8 gallons per minute — a typical 45-minute thaw cycle wastes:

8 gallons × 45 minutes = 360 gallons per batch

Many kitchens thaw multiple items per day. As shown in our

Defrosting Time Guide:

https://cnsrv.com/pages/defrost-guide

— thawing is not a short process under a faucet.

Extrapolated annually, a single kitchen easily wastes:

500,000–1,000,000 gallons of potable water per year.

More details and calculations in:

How Much Water Kitchens Waste When Thawing Food

https://cnsrv.com/blogs/news/how-much-water-kitchens-waste-when-thawing-food-with-real-numbers

The Financial Cost: $10,000–$20,000 Per Kitchen, Per Year

Commercial water + sewer rates often fall between $0.02–$0.04 per gallon.

At 500,000–1,000,000 gallons wasted annually, that means:

-

$10,000–$20,000 in unnecessary water costs

-

per location

-

every year

Multi-unit operators feel this most:

-

10 locations → $100K–$200K per year

-

50 locations → $500K–$1M per year

This doesn’t include labor loss, compliance risk, or quality degradation.

Labor Costs You Don’t See — But Definitely Pay For

Running-water thawing also creates hidden operational inefficiencies:

-

Staff must babysit the thawing process

-

Food thaws unevenly, slowing prep

-

Sinks stay blocked for long periods

-

Operators flip or reposition product under the stream

-

Inconsistent thaw times disrupt production schedules

Running water is unpredictable — which is why we compare thawing methods here:

Cold Water vs Walk-In vs CNSRV — Which Is Actually Best?

https://cnsrv.com/blogs/news/cold-water-vs-walk-in-vs-cnsrv-which-thawing-method-is-actually-best

The Bigger Problem: Uneven, Unsafe, Low-Quality Thawing

Beyond waste, running water is simply not effective:

-

Only one small area of the food receives direct water contact

-

Most of the surface sits in warm, stagnant pockets

-

Tap water frequently exceeds 70°F in warmer months

-

Edges thaw too quickly while the center stays frozen

-

Staff compensate with risky shortcuts

These issues are explained in-depth in:

Why Full Surface Contact Is Critical in Safe and Efficient Food Thawing

https://cnsrv.com/blogs/news/why-full-surface-contact-is-critical-in-safe-and-efficient-food-thawing

And in:

Why Continuous Water Movement Matters

https://cnsrv.com/blogs/news/why-continuous-water-movement-matters-in-food-thawing

Poor thawing = poor food.

This is especially true for fish and poultry, as covered in:

How Long Does It Take to Thaw Salmon?

https://cnsrv.com/blogs/news/how-long-does-it-take-to-thaw-salmon-a-complete-guide-for-commercial-kitchens

and

The Safest Way to Thaw Chicken

https://cnsrv.com/blogs/news/the-safest-way-to-thaw-chicken-a-food-safety-expert-guide

A Better Way: Controlled Cold-Water Thawing

Food scientists agree:

Cold-water thawing produces the best food quality and safety outcomes — as shown in:

Why Cold-Water Thawing Produces the Highest-Quality Food

https://cnsrv.com/blogs/news/why-cold-water-thawing-produces-the-highest-quality-food

But cold-water thawing only works when:

-

Food is fully submerged

-

Water actively circulates

-

Temperature stays below 70°F

-

Thaw time is predictable and standardized

That’s exactly what CNSRV was designed for.

See the system here:

CNSRV DC:02

https://cnsrv.com/collections/cnsrv-products/products/cnsrv-dc-02

And the compatible filter system here:

Soft Disposable Filters

https://cnsrv.com/collections/cnsrv-products/products/cnsrv-soft-disposable-filters

The Bottom Line

If your kitchen is thawing under a running faucet, it is:

-

Wasting 500,000–1,000,000 gallons of water per year

-

Losing $10,000–$20,000 annually per location

-

Burning labor and blocking prep sinks

-

Producing unsafe, inconsistent, low-quality results

These losses are completely avoidable.

Modern solutions like CNSRV turn thawing into a controlled, safe, efficient, predictable process — reducing water use by up to 98% and dramatically improving kitchen operations.

To learn more about how CNSRV works across foodservice environments, see:

https://cnsrv.com/blogs/news/cnsrv-featured-in-food-and-wine